|

||||||

|

||||||

| home products position controls SERS overview | ||||||

| SERS/WSERS overview | ||||||

|

||||||

| Stepping motor positioning control for 2-phases-stepping

motors with RS232, RS485, Profibus-DP or CANopen interface and features as follows: |

||||||

| flexible but easy programmable position control with many special functions | ||||||

| cost effective single or multiple axis control | ||||||

| microstepping power amplifer with 12800 steps/revolution | ||||||

| easy programmable via standard-windows-PC free programming software for SERS/WSERS with RS232 interface |

||||||

| Alternative programming and operation via hand programming

device (4x16 character-display with 16-key membrane keyboard) |

||||||

| eurocard-format for 19 inch 3HE systems for external

DC-supply or complete panel mount or 19 inch rack systems with integrated power supply (230VAC-50/60Hz) |

||||||

| compact housing version

WSERS xx.80 and WSERS xx.230AC with 4A or 8A for 20-80VDC supply or 4A or 6A for direct mains supply (115VAC/230VAC-50/60Hz) |

||||||

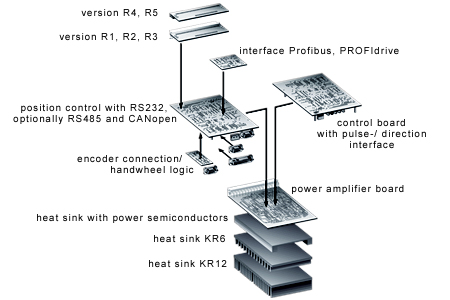

| flexible system due to modular design including up to 3 axis 12A/phase with power supply or 5 axis 12A/phase without power supply in one rack or up to 6 axis 4,2A/phase with power supply or 8 axis 4,2A/phase without power supply in one rack |

||||||

| easy installation of the panel mount / 19 inch system because of screw terminals / spring loaded terminals for all connections like supply, motor, inputs, limit, home and stop switches |

||||||

| The SERS is a point to point stepping motor

position control for 2-phases-stepping motors The SERS is available in different versions with: |

||||||

| phase currents from 0 to14,5 A/phase (programable via interface) | ||||||

| power supply 24 VDC until 240 VDC | ||||||

| optionally mains ready (230VAC 50Hz – optionally

also for 115 VAC 60Hz) panel mount system or standard 3 height unit 19 inch system |

||||||

| The SERS is controlled and programmed via a serial interface

(in standard version RS232C/V24). Optionally there are versions with RS485, Profibus DP, PROFIdrive or CAN open interface |

||||||

|

||||||

| Operation modes: | ||||||

| All operation modes are implemented in all standard SERS controls. The operation mode is selected by setting parameters and the structure of programming |

||||||

| Serial mode | ||||||

|

||||||

| In the serial mode the SERS is controlled via the serial interface

by a PC, PLC or NC. New positions (optionally with indication of velocity and acceleration, in case these values are changed) are sent via the serial interface and the SERS is started by sending an "execution" command. Inputs and outputs may be read and set any time. Also stored subroutines in the E²prom of the SERS may be called and started via the serial interface. By reading the corresponding parameters it can be checked any time, if the SERS is still buisy with executing a positioning job or a called subroutine. |

||||||

| Parallel / BCD mode | ||||||

|

||||||

| In this mode, different programms or just single commands are stored

into the E²prom of the SERS. The stored programms/commands can be selected with up to 7 digital inputs (address lines) and be started by a start (strobe) signal. In that way a PLC may select via its digital outputs up to 128 different programs in a SERS. |

||||||

| Master-Slave mode | ||||||

|

||||||

| 2 or more SERS are connected via the RS232-interface. One of the

SERS is configured as MASTER, the other SERS as SLAVES. The MASTER-SERS controls the SERS-SLAVES via the serial interface. The MASTER-SERS may send positioning jobs to the SLAVES and start them and at the same time execute a positioning job itself. Inputs and outputs of the SLAVES can be requested and set. The MASTER-SERS is able to start subroutines stored in the SERS-SLAVES and may request the status of the SERS-SLAVES. |

||||||

| Standalone mode | ||||||

|

||||||

| The SERS is operating independently of other controls or axis.

A stored operational program in the E²prom of the SERS is executed after a program start signal at an digital input or after power-on. In the program defined positions and commands are executed one after the other. The running program may be programmed in a way, that it depends on digital inputs, and outputs may be set or reset. |

||||||

| Manual mode | ||||||

| The digital inputs can be defined as manual (jog) functions. When

activating the inputs, the corresponding functions are executed. Following functions are implemented: |

||||||

| jog slow left and right | ||||||

| jog fast left and right | ||||||

| homing procedure | ||||||

| motor current ON / Motor current OFF - reset errors / warnings | ||||||

| stop | ||||||

| start operational programm | ||||||

| All manual functions are available also in the other operation

modes (e.g it can be defined that in the serial mode jog slow functions are available at inputs I1 and I2, and the other inputs are free programmable) |

||||||

| Download | ||||||

| stepper motors I position controls I power amplifiers I equipment I home I info@stoegra.de | ||||||